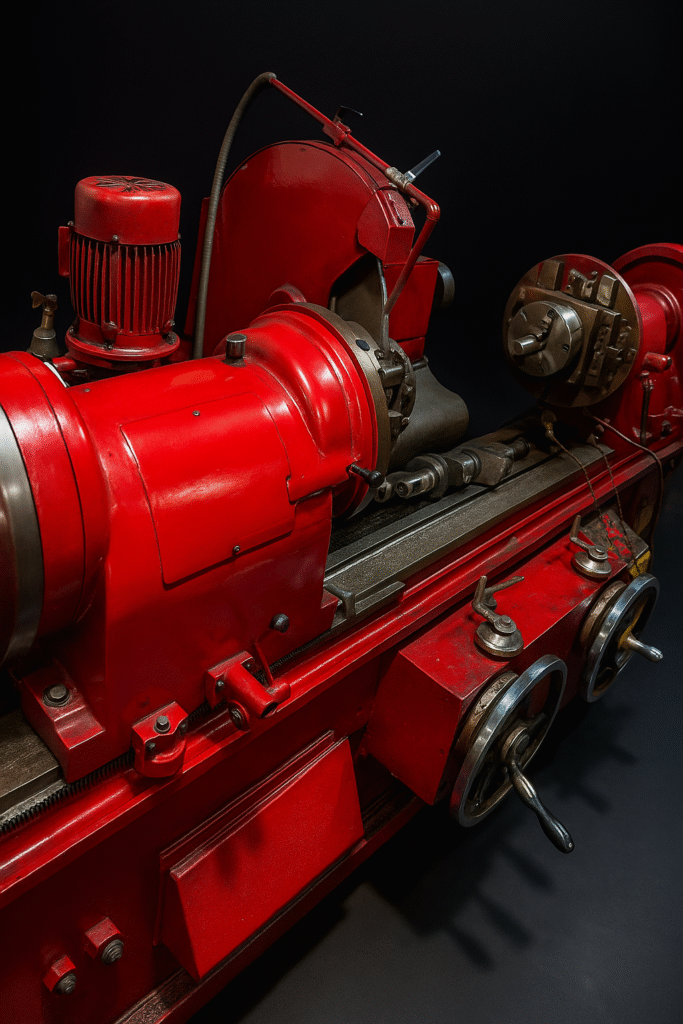

At Central Engineers, we deliver precision crankshaft cutting and grinding services as a key part of our complete engine rebuilding solutions. The crankshaft is a critical component that converts combustion force into rotary motion—so any damage or wear directly affects engine performance, fuel efficiency, and reliability. Our advanced crank shaft grinding machines are designed to restore crankshafts to fit the engine with high accuracy and smooth finishes.

Our facility is equipped with state-of-the-art crankshaft grinders and cutting machines capable of handling a wide range of engine types—whether from automotive engines, earthmoving equipment, marine engines, diesel generators, or industrial power units.

Our Crankshaft Machining Capabilities:

- Regrinding and re-cutting of crankshaft main and connecting rod journals

- Undersize grinding to compensate for wear and scoring

- Journal radius correction and chamfering

- Thrust surface restoration and polishing

- Dynamic balancing to ensure vibration-free operation

- Crack inspection and alignment checks

Why Crank Cutting Is Important in Engine Rebuilding

Over time, crankshafts may suffer from wear, overheating, oil starvation, or scoring, leading to power loss and engine knock. By carefully machining the journals and polishing the surface, we restore the geometry and finish necessary for proper oil film formation, bearing support, and efficient rotation.

Our trained technicians follow strict quality control procedures, ensuring each crankshaft is thoroughly inspected before and after machining for straightness, hardness, and dimensional accuracy. We use calibrated micrometers, surface finish testers, and alignment tools to guarantee precise results.

Industries We Serve:

- Automotive and commercial vehicles

- Construction and earthmoving machinery

- Marine and offshore engines

- Industrial power generation and compressors

- Agricultural engines and equipment

At Central Engineers, our crankshaft reconditioning services are often bundled with other engine machining operations such as:

- Line boring

- Cylinder honing

- Facing

- Cylinder head valve seat cutting & crafting

- Vertical boring and sleeving

We are proud to be one of India’s reliable engine rebuild service providers, delivering cost-effective, long-lasting solutions for worn or damaged crankshafts. Whether it’s a single job or part of a full engine overhaul, we ensure the highest standards of precision, workmanship, and turnaround time.

Why Choose Central Engineers?

- Decades of experience in engine rebuilding

- Skilled technicians and certified processes

- In-house machining capabilities

- Competitive pricing with fast delivery

- Trusted by leading industries across India

If you’re facing crankshaft issues or planning a full engine overhaul, contact Central Engineers today. We’ll bring your engine back to life—with power, precision, and performance that lasts.