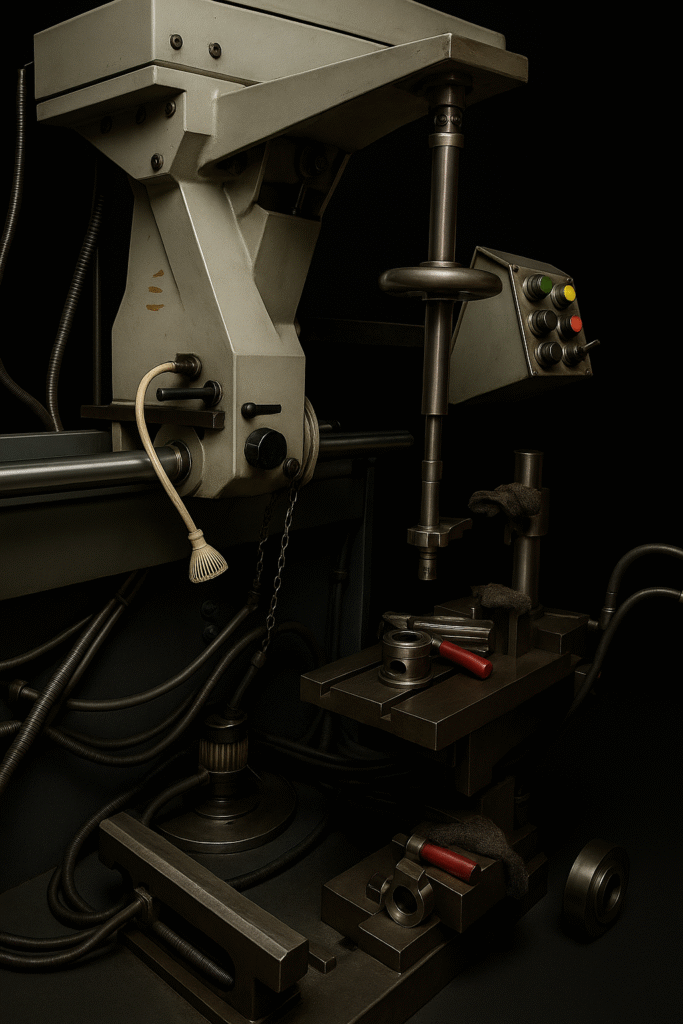

At Central Engineers, honing is a key process in our engine rebuilding operations, ensuring that engine cylinders and liners are restored to exact specifications for smooth and efficient performance. Our advanced honing machines are specially designed to achieve the perfect surface finish, diameter accuracy, and crosshatch pattern required for optimal piston and ring function.

In the engine rebuilding process, cylinder honing plays a critical role in improving oil retention, sealing efficiency, and extending engine life. Whether it’s a diesel engine from a construction machine or an industrial power unit, our honing services bring worn cylinders back to life with precision and consistency.

Our Honing Services Include:

- Cylinder honing after reboring

- Finishing and sizing of engine blocks and liners

- Creating ideal crosshatch patterns for oil retention

- Honing for automotive, industrial, earthmoving, and marine engines

- Restoration of cylinders to OEM specifications

Our team of experienced technicians ensures each cylinder is honed to exact tolerances for optimal compression, minimal oil consumption, and long-term reliability. The process is often part of our full engine rebuild packages, which include line boring, crankshaft grinding, facing, and vertical boring.

With a strong reputation in the Indian engine rebuilding industry, Central Engineers is trusted for quality, precision, and dependable service. We combine advanced equipment with technical know-how to deliver engine components that perform like new.